CNC Turning types stainless steel / aluminum flexible coupling for motor

Curved Jaw Couplings

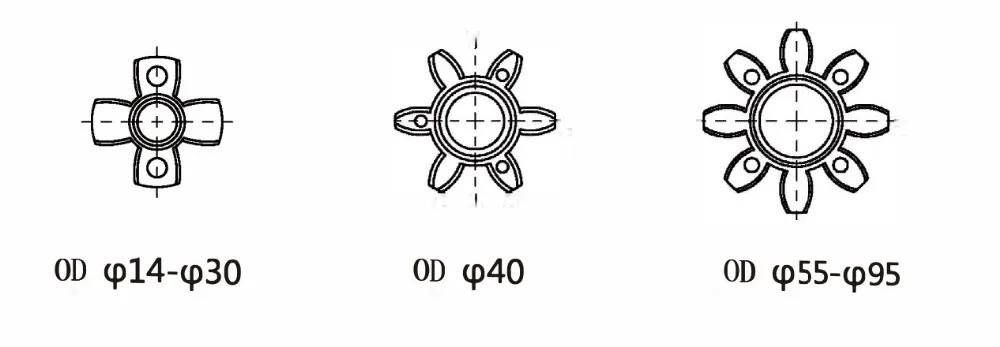

The Curved Jaw couplings can be utilized in many applications and serve as an all-purpose coupling. The basic design of the Curved Jaw allows for al higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it the high torque capacity, and reduces edge pressure. It will accommodate axial, radial and angular shaft misalignments.

The hubs are produced from a variety of materials including: aluminum, gray ,iron, steel, sintered steel, and stainless steel. The spider elements are available in various durometer options in Urethane & Hytrel. The spiders can perform under normal duty cycle conditions to heavy duty cycles which include shock loading and can minimize torsional vibrations in the system.

|

Model

|

Bore size (mm)

|

RatedTorque (N.m)

|

MaxTorque(N.m)

|

Max speed

|

Outer Diameter (mm)

|

Length (mm)

|

Bore Tolerance (mm)

|

|

HS -TCN-14C

|

3~7

|

0.7

|

1.4

|

45000

|

14

|

22

|

+0.6~0

|

|

HS-TCN-20C-R

|

4~11

|

1.8

|

3.6

|

31000

|

20

|

30

|

+0.8~0

|

|

HS-TCN-30C-R

|

6~16

|

4

|

8

|

21000

|

30

|

35

|

+1.0~0

|

|

HS-TCN-40C-R

|

8~28

|

4.9

|

9.8

|

15000

|

40

|

66

|

+1.2~0

|

|

HS-TCN-55C-R

|

9.5~32

|

17

|

34

|

11000

|

55

|

78

|

+1.4~0

|

|

HS-TCN-65C-R

|

12.7~38.1

|

46

|

92

|

9000

|

65

|

90

|

+1.5~0

|

Spider Characteristics

The curved jaw coupling includes two metal hubs and an elastomeric “spider” element. The spiders are available in

different hardness durometers, each easily identified by its color.

|

Hardness

|

Color

|

Material

|

Temperature Range

|

Applications

|

|

80 Shore A

|

Blue

|

Polyurethane

|

-50 ~+80 .C

|

Excellent damping

|

|

92 Shore A

|

Yellow

|

Polyurethane

|

-40~+90 .C

|

Moderate damping, general applications

|

|

98 Shore A

|

Red

|

Polyurethane

|

-30 ~+90 .C

|

High torque applications

|

|

64 Shore D

|

Green

|

Polyurethane

|

-50 ~+120 .C

|

Higher torque, high temperature

|

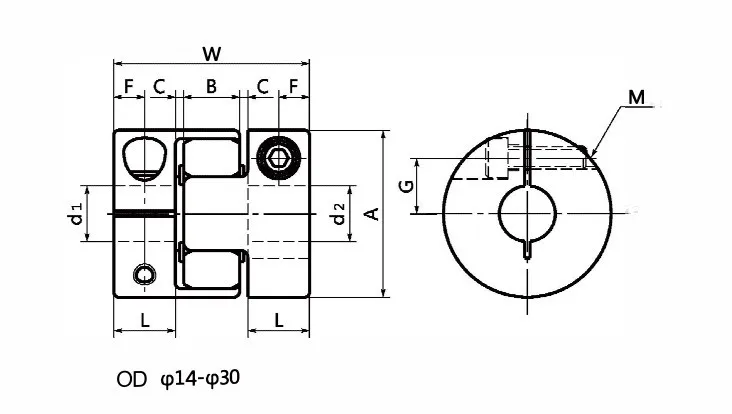

Coupling measure information

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

14

|

7

|

22

|

6

|

1

|

3.5

|

4/5

|

M2/M1.6

|

|

20

|

10

|

30

|

8

|

1

|

5

|

6.5/7.5

|

M2.5/M2

|

|

30

|

11

|

35

|

10

|

1.5

|

8.5

|

10/11

|

M4/M3

|

|

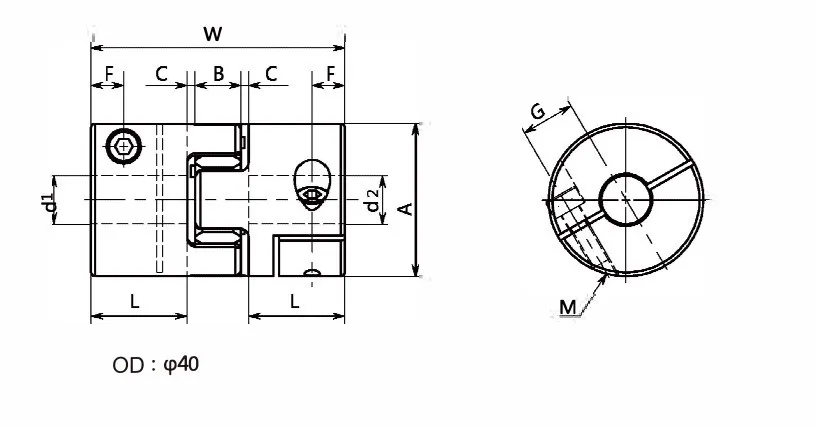

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

40

|

25

|

66

|

12

|

2

|

8.5

|

14/15.75

|

M5/M4

|

|

A

|

L

|

W

|

B

|

C

|

F

|

G

|

M

|

|

55

|

30

|

78

|

14

|

2

|

10.5

|

20/21

|

M6/M5

|

|

60

|

35

|

90

|

15

|

2.5

|

13

|

24/25

|

M8/M6

|