Micro M415 nema 17 stepper motor driver

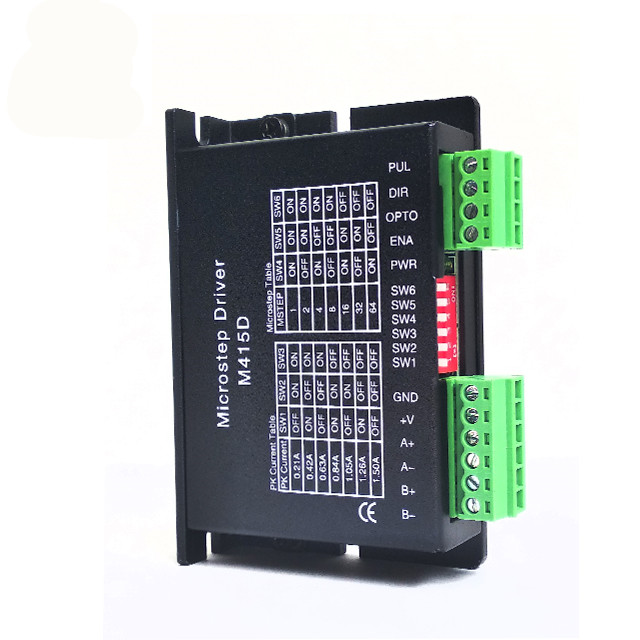

M415D

Stepper Motor Driver Specification

Overview

The M415D is a new generation microstep stepper motor driver which applies original imported chips. Due to the adoption of the advanced bipolar constant-current chopper driver technology, it shows stable operation, provides excellent high torque. Moreover, it significantly reduces the noises and vibration of the operating motor. The M415D has the feature of low-noise, low-vibration and low-heating. The M415D is DC18-40V power supply. It applies to 2-phase hybrid stepper motor under 1.5A current, such as 57,42series stepper motor. The M415D has several kinds of microsteps. The maximum step number is 12800 steps/rev (microstep is 1/64). The peak operating current ranges from 0.21A to 1.5A., and the output current has 7 stalls. The M415D has automatic semi-flow, motor misconnected protection functions and so on.

Applications

It can be applied in a variety of small scale automation equipment and instruments, such as labeling machine, cutting machine, packing machine, drawing machine, engraving machine, CNC machine and so on. It always performs well when it is used in equipment which requires for low-vibration, low-noise, high-precision and high-velocity.

Current selection

|

Peak |

SW1 |

SW2 |

SW3 |

|

0.21A |

off |

on |

on |

|

0.42A |

on |

off |

on |

|

0.63A |

off |

off |

on |

|

0.84A |

off |

on |

off |

|

1.05A |

off |

on |

on |

|

1.26A |

on |

off |

off |

|

1.50A |

off |

off |

off |

Microstep selection

|

Pulse/Rev |

SW4 |

SW5 |

SW6 |

|

200 |

on |

on |

on |

|

400 |

off |

on |

on |

|

800 |

on |

off |

on |

|

1600 |

off |

off |

on |

|

3200 |

on |

on |

off |

|

6400 |

off |

on |

off |

|

12800 |

on |

off |

off |

Driver functions descriptions

|

Driver function |

Operating instructions |

|

Output current setting |

Users can set the driver output current by SW1-SW3 three switches.

The setting of the specific output current, please refer to the instructions of the driver panel figure. |

|

Microstep setting |

Users can set the driver Microstep by the SW4-SW6 three switches. The setting of the specific Microstep subdivision, please refer to the instructions of the driver panel figure. |

|

Signal interfaces |

PUL is the setting pulse input; DIR is the stepper motor direction input; OPTO is the power supply for signal port + 5V; ENA is the motor free input. |

|

Motor interfaces |

A+ and A- are connected to a phase winding of motor; B+ and B- are connected to another phase winding of motor. If you need to backward, one of the phase windings can be reversed. |

|

Power interfaces |

It uses DC power supply. Recommended operating voltage is 18VDC-40VDC, and power consumption should be greater than 100W. |

|

Installation instructions |

Driver dimensions:86×55×20mm, please refer to dimensions diagram. Please leave 10CM space for heat dissipation. During installation, it should be close to the metal cabinet for heat dissipation. |

Signal interface details:

The internal interface circuits of the driver are isolated by the opt coupler signals, R in the figure is an external current limiting resistor. The connection is differential. And it has a good anti-jamming performance.

Control signal and external interface:

|

Signal amplitudes |

External current limiting resistor R |

|

5V |

Without R |

|

12V |

680Ω |

|

24V |

1.8KΩ |