The air conditioner motor is one of the most important components of the air conditioner. Without the motor, the air conditioner loses its meaning.

Air-conditioning motors mainly include compressors, fan motors (axial fans and cross-flow fans), and swing air supply blades (stepping motors and synchronous motors)

Single-phase asynchronous motor

Single-phase compressors for air conditioners have two windings, namely the starting winding and the running winding (main winding), and three terminals, which are the common terminal, the starting terminal and the running terminal, which are generally driven by capacitor operation and implement constant speed control.

During the process of starting the motor to the normal operation, the auxiliary winding circuit is always connected with a capacitor in series, so that the electrical appliance has good running performance, high efficiency and power factor, and works reliably.

Three-phase asynchronous motor

Its structure is similar to that of a single-phase motor. The difference is that the stator of a three-phase motor is composed of three sets of completely symmetrical windings. These three windings are embedded in the stator core slots and are staggered by 120° electrical angle in spatial distribution.

The three windings can be connected in a Y shape or a △ shape. When three-phase symmetrical currents are passed into the stator windings (that is, the three-phase currents differ by 120° in terms of time and phase), the The air gap between the rotors generates a rotating magnetic field, which causes the rotor to generate electromagnetic torque due to electromagnetic induction.

The three-phase asynchronous motor has a simple structure and excellent performance. The torque, efficiency and power factor are higher than those of the single-phase asynchronous motor. Therefore, air conditioners with higher power, such as cabinet air conditioner compressors, mostly use three-phase asynchronous motors.

Principles of motors used in other air conditioners

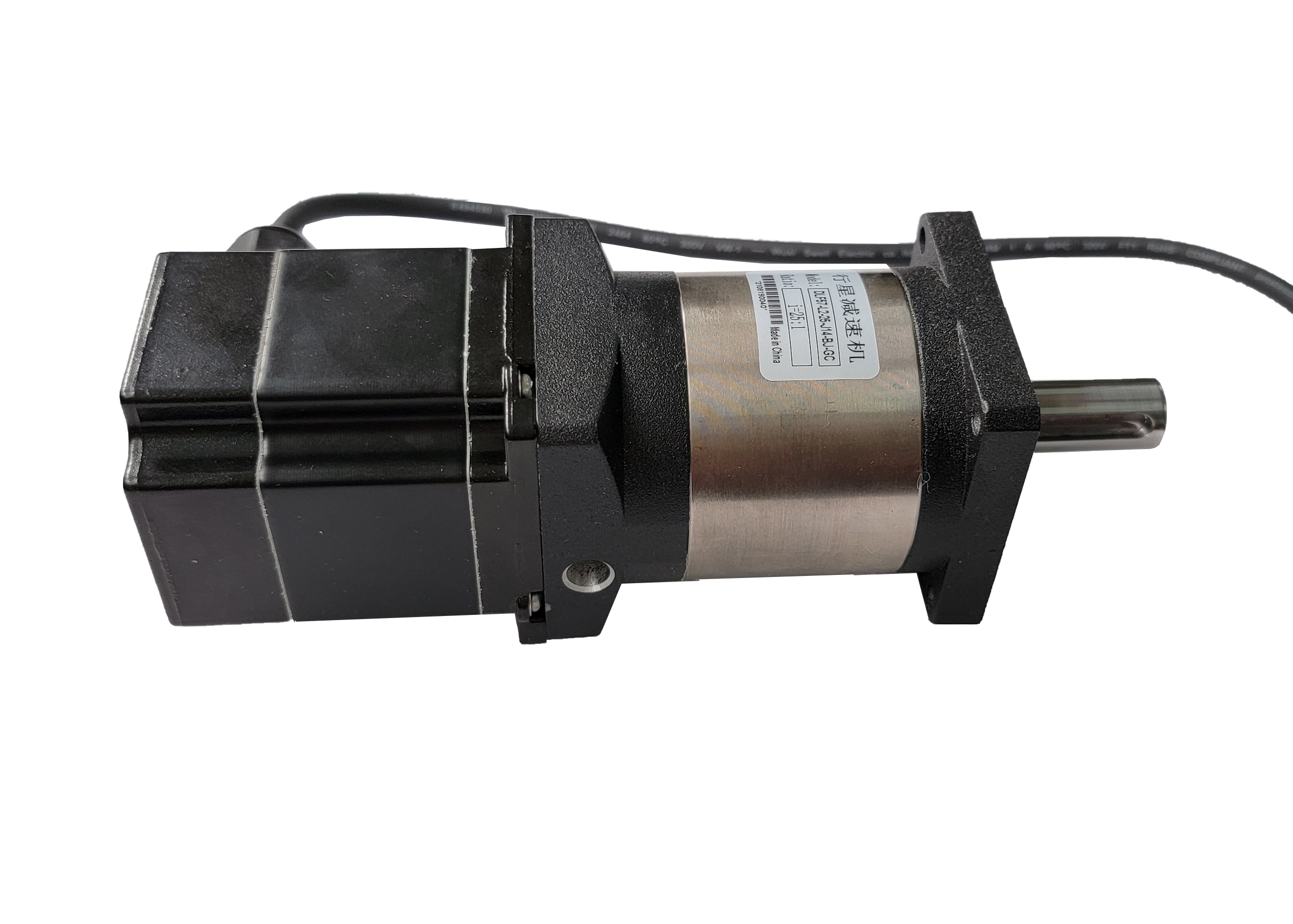

1. Stepper motor

A stepper motor is an executive element that converts electrical pulse signals into linear displacement or angular displacement, that is, when a pulse signal is applied to the motor, the motor moves one step.

The rotor is a cylindrical two-pole permanent magnet rotor made of permanent magnets. The inner circle of the stator and the outer circle of the rotor have a certain eccentricity, so the air gap is uneven, and the air gap is the smallest, that is, the magnetic resistance is the smallest.

A concentrated winding is set in the stator armature, and electric pulse signals are added to both ends of the winding by a special power supply. When the stator winding is not energized, there is a magnetic flux generated by the permanent magnet rotor in the magnetic circuit of the motor.

This flux will tend to the axis of the rotor poles towards the position in the magnetic circuit where the reluctance is minimal.

When the power supply adds a pulse to the motor winding, the polarities of the two magnetic poles of the stator and the two magnetic poles of the rotor are repelled, and the rotor rotates about 180° counterclockwise in the direction of the arrow n until the magnetic poles of the stator and the opposite poles of the rotor are opposite.

2. Permanent magnet synchronous motor

The micro-motor used in the air-conditioning outlet grill swing blade device is a permanent magnet synchronous claw-pole self-starting synchronous motor.

The motor driving voltage is ~220V/50Hz, and its stator consists of a cup-shaped casing, an annular single-phase coil and claw pole pieces; the rotor is a ferrite ring with high coercivity.

The claw poles are evenly distributed along the circumference, and the number of claw pole pairs (magnetic pole pairs) is determined by the required synchronous speed. The swing motor has many claw pole pairs, low speed, large torque, small output power, simple structure and no fixed steering. The master switch is usually installed on the control panel of the air conditioner. It is the power switch to connect the compressor, fan and other executive equipment, and also the selector switch to switch the running state of the air conditioner.

By Jessica

Post time: Mar-07-2022